Reliability in an emergency shutdown (ESD) system is paramount. Until now, there has not been a rational solution to cycle an ESD solenoid equipped with a Latching Manual Reset during a partial valve stroke test (PVST).

During this procedure, once the ESD is de-energized, the solenoid latches and will not reset on a signal due to the manual reset function. In most instances, a bypass circuit is created to PVST the process valve, which bypasses the ESD Latching Manual Reset Solenoid Valve. This test does not cycle and test the critical ESD solenoid valve.

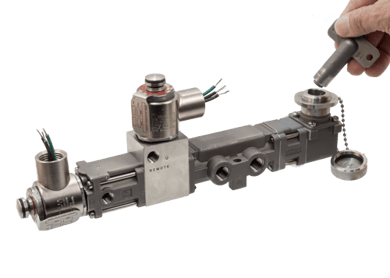

Today, Versa provides an innovative field-proven solution that combines an ESD solenoid, an air latch manual reset, and a remote reset solenoid to enhance the PVST solenoid with Local and Remote Latching Manual Reset functionality.

Today, Versa provides an innovative field-proven solution that combines an ESD solenoid, an air latch manual reset, and a remote reset solenoid to enhance the PVST solenoid with Local and Remote Latching Manual Reset functionality.

These exclusive combination actuator options enable this unique solution that improves both reliability and safety.

The key to this solution is an air latch pilot with a remote pilot override, rather than a mechanical or electric latching mechanism. Air Latch Pilot and Remote Reset pilots have been part of Versa's reliable “Air Logic” offshore control shutdown systems for more than 30 years (with the Air Latch pilots in service since the 1970s). These dependable features can now be applied together to improve process reliability.

Testing the ESD solenoid valve during PVST improves the reliability of the critical process valves.

Our new solution not only increases product performance but also the plant's safety. The solenoids may also be independently exercised (cycle & tested) periodically without interrupting the process, decreasing the PFD (probability of failure on demand) for the PVST. The testing can be monitored and logged to assure performance compliance.

Installation Advantages

This Versa valve has the same mounting footprint as any V-316 Valve. Its thoughtful design provides extra convenience during installation with all solenoid and sensor wires on the same side to simplify electrical connections.

Its all-in-one valve "package" removes hours of engineering design and installation labor. Due to the Versa innovative "1 valve circuit”, hard material costs such as tubing, fittings, multiple valves, and mounting hardware are significantly reduced.

In essence, this one valve takes the place of a complex circuit which would require quite a large panel. Instead, this valve measures a compact 12”x2”. To enhance Real World Reliability, a filter/regulator can be incorporated creating a V-MAP.

High Flow

The Versa V-316 series is available in three high-flow sizes enabling standardization of the reliable Versa product offering throughout the plant:

- 1/4" NPT at 1.8 Cv

- 3/8" NPT at 2.0 Cv

- 1/2" NPT at 5.5 Cv

Reset Options

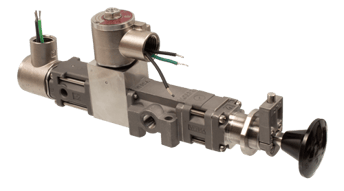

Palm Button

If the keyed reset is not necessary and a local function is preferred, we offer some options for manual operation and local latch reset. A palm button option requires “pulling” the palm button to reset with the solenoid energized.

One can also manually operate the valve (without solenoid energized), but the operator must pull and hold the palm button. Once the button is released the valve will close.

Palm Button Pull & Pin

We do offer a “Pull & Pin Option.” This option provides manual override by pulling the knob and depressing the pin to hold the valve open. When the knob is pulled again and released, the pin no longer keeps the valve open. Releasing the knob closes the valve.

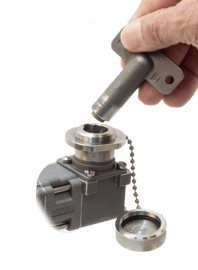

Key Operation

For applications where additional safety requirements exist, Versa offers a unique key-operated manual reset instead of the palm button actuator shown above. This option requires the key to manually reset the valve thereby increasing the safety level and assuring that the valve cannot be mistakenly actuated.

ESD solenoid

The other mode of reset is to energize the ESD solenoid. When this occurs, the manual operation is no longer active and the ESD solenoid is now the controlling factor. This option was created in the 1970s as part of Versa offshore wellhead control panel logic.

Sensor Options

The valve feature functions can provide pressure feedback from:

- The Remote and ESD pilot chamber (-20).

- The spool position

Utilizing these 3 "pressure" ports creates a plethora of monitoring combinations to indicate the functional position of the solenoid valve's programmed processes.

If all the bells and whistles of digital pressure sensors and transducers aren’t required, users can equip their ports with pressure gauges or Versa status indicators (winkies). Winkies will provide a visual indication of which solenoid is providing the pressure holding the valve open and the spool position.

If the process valve already has a solenoid, or bypass circuit, the existing solenoid(s) can be integrated by using a remote pilot and air latch pilot combo.

Along with the valve, its features and options, Versa offers incomparable product reliability, durability, customer service, market knowledge, and application prowess all backed by our 10-year warranty. All of this from a privately held company and factory in the USA provides a bedrock of “Real World Reliability” and service for our customers.

For more information, contact your local Distributor.

Engineered to Outperform and Outlast all Others