REAL WORLD CHALLENGES

An unmanned natural gas compressor station in a remote location in West Virginia required solenoid valves with a manual reset option on their Emergency Shutdown (ESD) system. When normal wear and tear caused solenoid failures, it would take hours for a technician to reach the site, troubleshoot, and perform the necessary routine maintenance. These unplanned shutdowns caused significant downtime and lost revenue for the facility.

An unmanned natural gas compressor station in a remote location in West Virginia required solenoid valves with a manual reset option on their Emergency Shutdown (ESD) system. When normal wear and tear caused solenoid failures, it would take hours for a technician to reach the site, troubleshoot, and perform the necessary routine maintenance. These unplanned shutdowns caused significant downtime and lost revenue for the facility.

THE VERSA SOLUTION

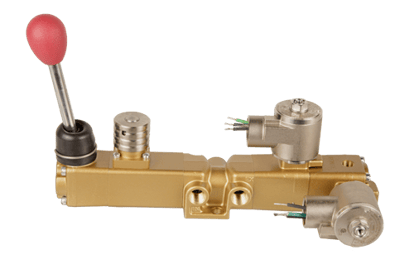

VERSA created a solution utilizing the V-Series Directional Control Valve with 2oo2 Redundant Solenoids (-RS) and Diagnostic Feedback (-20) options. This solution provides real-time remote indication of a solenoid failure while maintaining safe operation of the ESD system. This allows technicians to perform required maintenance in a controlled manner without interrupting facility operation – resulting in the optimization of revenue while maintaining reliability, performance, and safety.

2oo2 Redundant Solenoid (-RS):

VERSA’s 2oo2 Redundant Solenoid option is a specially designed redundant solution for ESD valves to achieve high system availability and prevent nuisance trips while meeting all the safety protocols.

Diagnostic Feedback (-20):

VERSA’s Diagnostic Feedback option adds an intelligence capability to our field-proven valves. Adding key modular components with the ability to integrate sensing devices enables the VERSA valve to provide strategic multipoint position feedback.

The VERSA model number used:

VAA-3321-B415-NGST-XV1-20-D024